Inventory forecasting often escapes its deserved amount of attention but it can actually be transformational for your business. Let’s put this in context within a story: imagine you have a wholesale chocolate business and your customers are florists. Valentine’s Day is coming soon and it’s time to get those chocolate orders in. They jump onto your website to place an order as they have their annual Valentine’s promotion on a very specific item that you stock. They have made this purchase every year for the last five years, and rely on your company to ensure that sufficient stock levels can meet their needs. But, today, you’re low on stock because you did not account for increased demand for this specific item and there is no way that you’d be able to fulfil the order at that volume. Your customer is now stuck, so they have two choices: change their choice of chocolate which has been established in their customer base for five years, or take what they can from you and go to your competitor for the balance required, hoping that they have enough in stock for them. It’s not a great position to be in as a customer, and not a good look as a wholesaler. The same goes for ecommerce businesses; overselling is a tangible issue which can affect listing position and lead to bad reviews.

This situation can be completely avoided if you forecast your inventory needs in advance. Every year for the last five years, they made the same order but in consistently growing quantities. If you were forecasting your inventory, then you’d know that they would need that item, in a higher quantity than what they had last year. But you didn’t and that customer’s faith in your company has diminished slightly.

Before we jump into it, let’s understand inventory forecasting and the four general types:

With all four of these types, the more data in, the better the forecast. However, they all have their own strengths and weaknesses.

As you would have gathered, inventory forecasting is exactly what it says on the tin: it predicts the demand for a specific product. In most cases, businesses predict this based on historical data and forecasted peaks, such as children’s toys at the Christmas season, or restaurant bookings in mid-February. This ensures that your business can cope with the influx of demand, and when done correctly, it can also safeguard your cash flow, ensuring that not too much of your money is tied up in unnecessary stock.

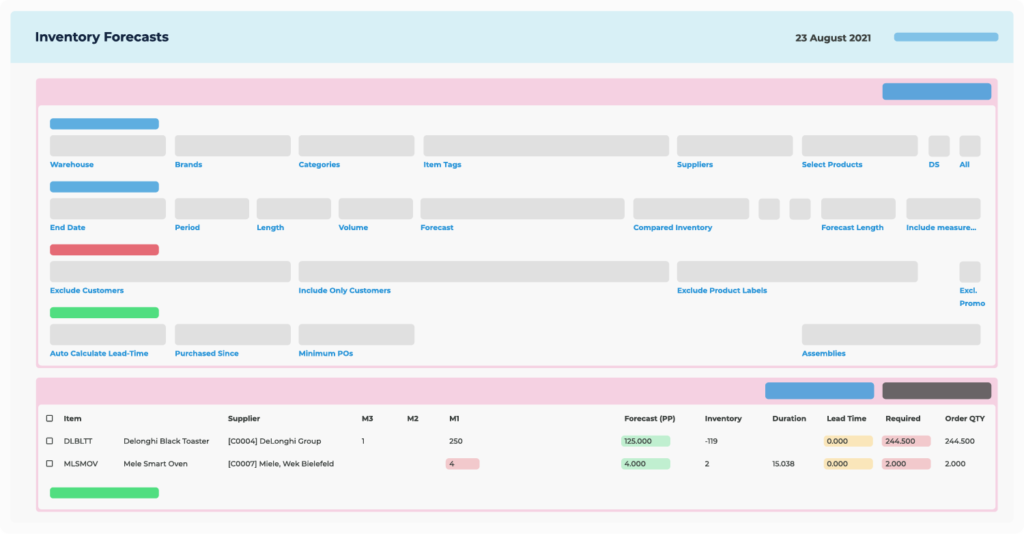

Yes, you read that correctly; inventory forecasting can help your bottom line. As product based businesses, a lot of capital is needed to get the ball rolling, and a large chunk of your cash is tied up in those products, waiting to be sold. You can’t sell something you do not have (unless you’re in a pre-sales phase which is different), so you have to buy the stock in order to sell it. Now with the pin-point inventory forecasting you get with TradePeg, you can accurately see what you should be stocking more of and free up the cash that’s normally tied up in slow moving stock. You can easily say sayonara to large volumes of dead stock with TradePeg.

TradePeg goes beyond just replenishing stock. It meticulously tracks stock movements and identifies consumer purchasing patterns, giving you, the business owner, the information you need to properly replenish your inventory in a timely manner, escaping the mad rush that occurs during peak seasons.

One of the keys of stock control and order management is knowing when inventory needs to be reordered. Some suppliers have a longer lead time than others, and if that’s the case, you’d want to get ahead of the ‘last-minute-dot-com’ crowds. You also have to take into account your storage space, and ensure that you have ample storage space for your forecasted inventory requirements.

This is where TradePeg can support your business. With the marriage of inventory management, automation and accurate demand forecasting, you can rest assured that your shelves would be stocked with your fan favourites, solidifying your reliability in your customers’ hearts. Keeping a close eye on stock control, you can know at any moment in time what is available, what’s running low, and what is critical. This gives you the oversight you need of your stock control.

Going beyond stock control, TradePeg can track the stock location in your warehouse, saving you and your time a lot of time searching, since you’re able to add barcodes, locations and categories to every single item.

We’re really proud of what we’ve built. It truly can revolutionise the way that your business forecasts inventory and how you manage your inventory during peaks and troughs. Imagine running a report and knowing exactly what items you’ll need for the coming peak, how much you’ll need to re-order, and being able to order right there and then.